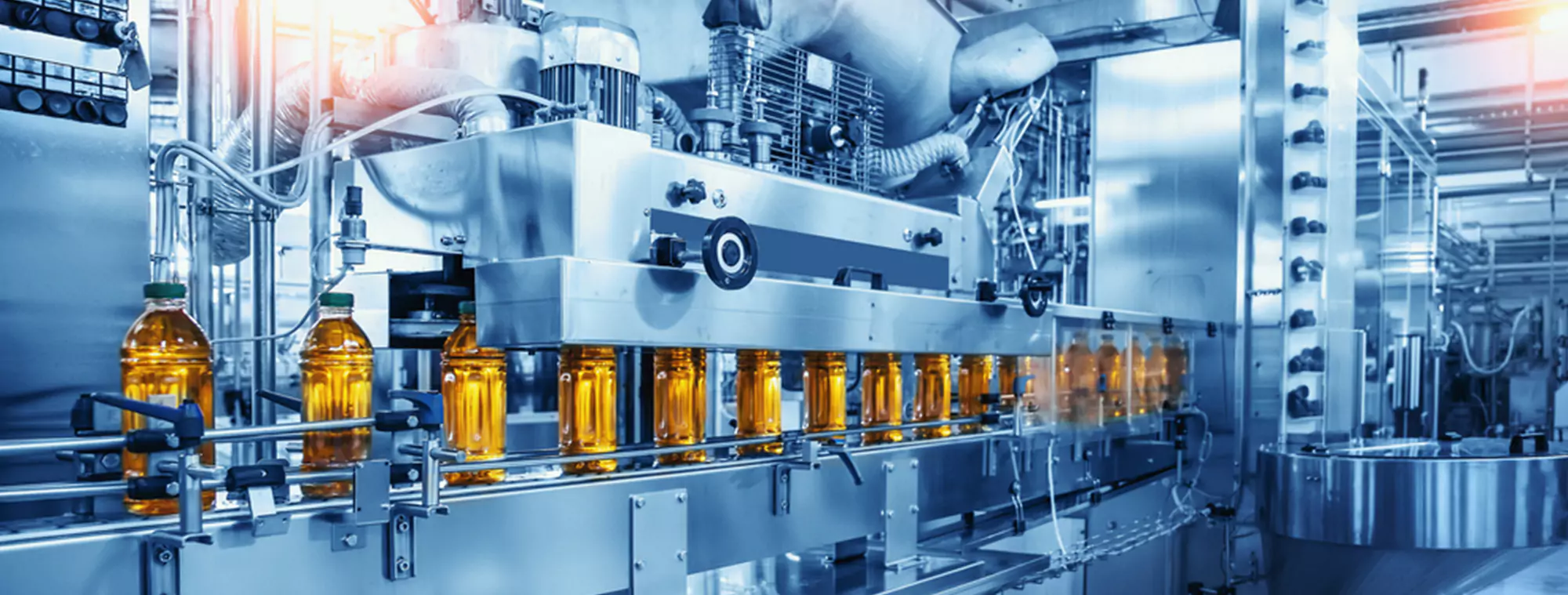

Injection moulding and extrusion are high-volume manufacturing processes often used in the food & beverage industry. Injection moulding involves the production of products by injecting molten materials into a mould. The materials can be metals and glasses, but most commonly food-grade thermoplastic and thermosetting polymers. Injection moulding is used to produce a variety of products that handle food and drinks before you ingest them, such as bowls, bottles and caps, containers for storage and serving hot foods and beverages, packaging materials and much more.

The extrusion process also includes melting and forming materials but instead of a mould the material is pushed through (extruded) a die of the desired cross-section. This can result in many different profiles or as a film, and be used in countless applications.

Since both these processes include melting and forming material the process is very energy intensive and the heat load generated in the extrusion/injection moulding process is massive. This is also the reason it makes great sense to focus on this process when it comes to energy saving potential. Removing heat (i.e. process cooling) is important for the efficiency rate of the cooling system, and the ability to recover this heat for other purposes can be very useful for lowering OPEX costs.

Compressed air can also play an important role within the process, for example in different parts of the assembly process etc. In blow moulding (film extrusion), it plays a vital part in the production process. We can guide you through the compressed air demands and design an efficient and reliable solution suited for your needs.

The ventilation efficiency and the way the air is supplied to the production hall is also very important, both for the operational costs and for the specific process needs. Depending on the product the demand can be for low particle levels, dew point control (to avoid condensation) or temperature control. AirSon’s long experience within both the injection and extruding industries and MEP services means we can help you design and build an efficient and reliable production facility meeting your process needs.