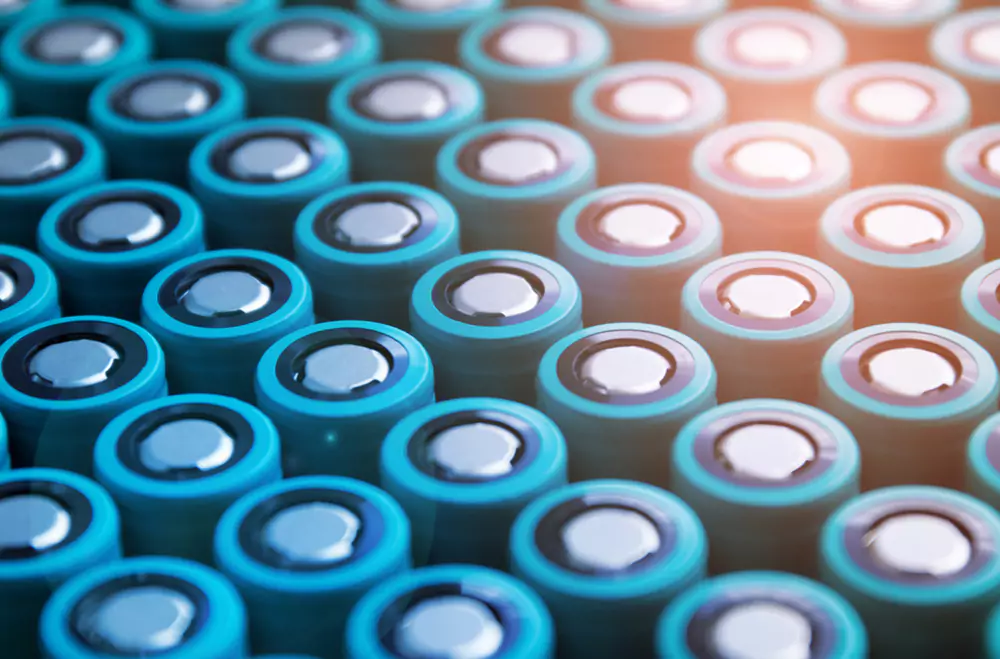

The world is becoming more and more dependent on batteries, no matter if we talk about the devices we carry in our pockets, the electrification of the transportation sector, energy storage or electrification in general.

Lithium-ion batteries stand out (at the moment) as one of the most promising technologies in the sector, thanks to their energy density, cost competitiveness and cycle life.

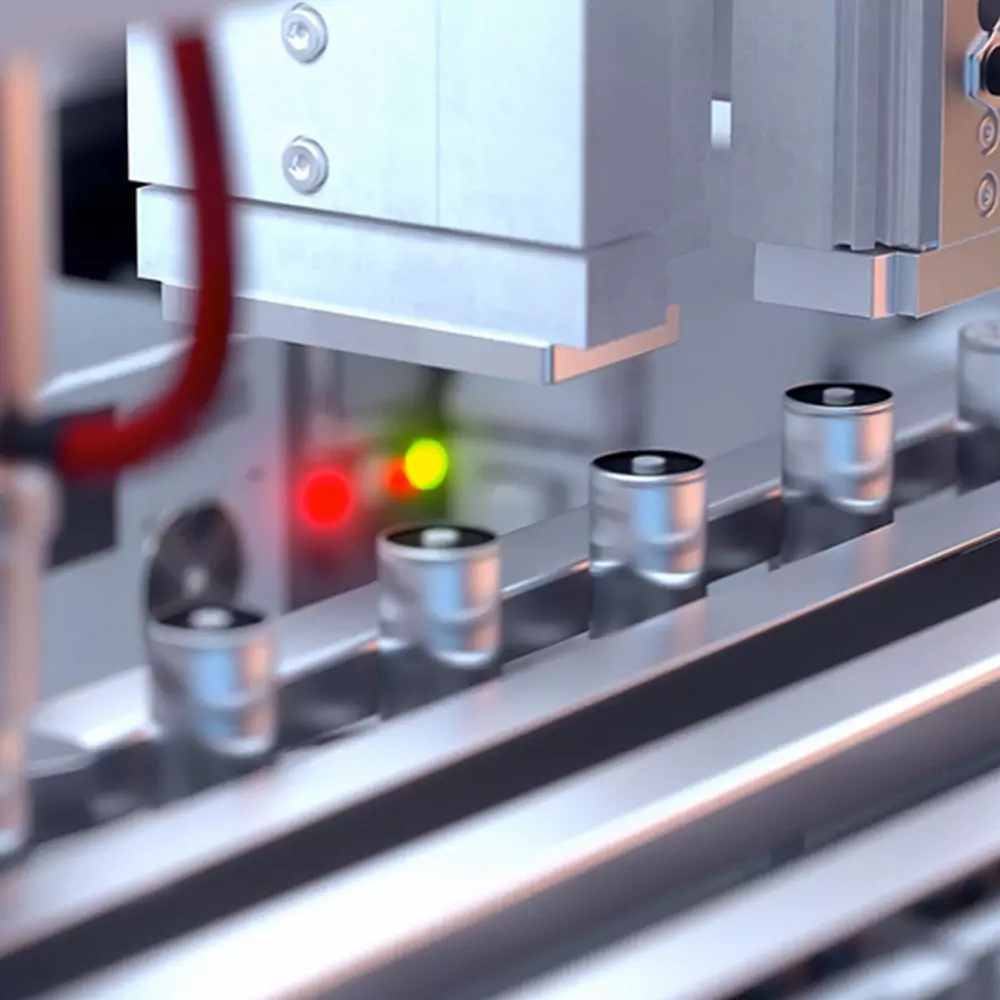

The Li-ion battery value chain is not just about the so called gigafactories. Sure, the cell assembly factories are the final part of the chain that puts all the different components together. But before being assembled, all of these components need to be produced. And that production process is far from simple. Most of the components require carefully controlled environments with tight tolerances when it comes to temperature, humidity, particles, etc. This is true for the anode and cathode materials as well as for the separator film and other components.