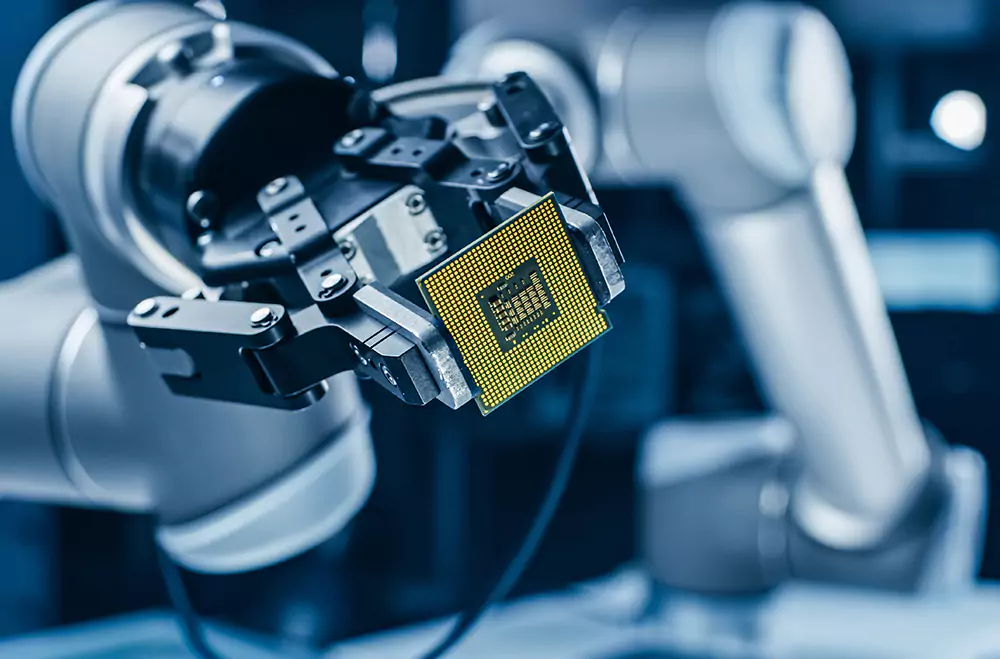

Futureproof and safeguard your production process and personnel in hi-tech environments

In the “Hi-tech Manufacturing” industry, i.e. microelectronics, optics, batteries, automotive, defense etc, there has always been a strong focus on process reliability, product quality and safety. These parameters of course still stand out, but there are also more requirements added that need to be part of the equation. Minimizing capital expenditure (CAPEX) and operational expenditure (OPEX) is of course key questions to address.

The product quality required in the market is often well documented and understood by the product manufacturer and so is the safety issue – this is key knowledge in any corporation. However, the demands on the supporting systems for the main production lines are not as defined. What is really needed in terms of performance of the ventilation system? Or the compressed air system? Or the steam systems? This is where AirSon comes in with expert knowledge to bridge our customers’ needs in term of top quality of the final product and optimum production reliability with the requirements of the utility systems.

For the newer industries in the Hi-Tech industry, there are often no best practices to rely on, as many processes have never existed before. We are used to such environments and circumstances, where the “SOP” (standard operating procedure) is not yet written. With our vast experience from industries with similar requirements, we can always give you recommendations on the best solution going forward. At AirSon, we are not afraid to stick our necks out to help guide you through new and unknown territories.

We make efficient, reliable high-tech production facilities come to life.